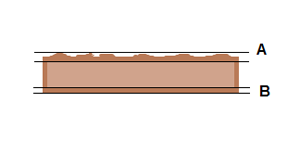

Laser Scribing ceramic substrates has been increasingly popular since its introduction to the industry nearly 50 years ago. The process involves pulsing a CO2 laser through an optical configuration, through a focusing lens, focusing the beam through an air assisted nozzle assembly, and finally onto the substrate's work surface. Most Laser scribing systems utilize a CNC or PC based motion control system, moving the substrate below the fixed beam assembly at speeds as fast as 10 in./sec, or faster. Each pulse of the Laser provides an efficient and effective evacuation of molten and ablated ceramic substrate particulates. Well executed scribes allow for subsequent controlled Breaks, or “Snapping”, of the substrate to its final size.